Drawing inspiration from palm trees, US researchers have found a way to significantly scale up offshore wind turbines — a development that could dramatically increase the amount of electricity we generate from wind power.

Offshore wind turbines: Wind turbines typically feature propeller-like blades attached to a large tower. As the wind hits the blades, they spin, and a generator converts that movement into electricity.

We can maximize the amount of electricity generated by a turbine by making its blades as large as possible, placing them on the side of the turbine that the wind hits first (“upwind”), and building the turbine offshore, where the wind blows fast and steady over the sea.

These approaches have tradeoffs, though. Building turbines offshore means they’re sometimes in the path of hurricanes, and if winds are too strong, massive blades can bend backwards and slam into the tower.

To reduce their risk, offshore wind turbines typically have thick, stiff blades that can better withstand strong winds — but those have drawbacks, too.

“Conventional upwind blades are expensive to manufacture, deploy, and maintain beyond 10 to 15 megawatt,” Todd Griffith, technical lead for the Sandia National Laboratories’ Offshore Wind Energy Program, told CleanTechnica in 2016.

“They must be stiff, to avoid fatigue and eliminate the risk of tower strikes in strong gusts,” he continued. “Those stiff blades are heavy, and their mass, which is directly related to cost, becomes even more problematic at the extreme scale due to gravity loads and other changes.”

In other words, it’s hard to build a turbine that can handle huge blades made from very heavy material. So offshore blades have to choose between size (more power) and strength.

“You’re talking about being able to power a small city with one of these wind farms.”

Eric Loth

The idea: We need larger turbines that are both cost-effective and capable of surviving hurricane-force winds — and the Segmented Ultralight Morphing Rotor (SUMR) turbine design might make that a reality.

Developed at Sandia National Laboratories and several US universities, SUMR turbines feature blades on the opposite side of the tower (“downwind”) from a standard turbine, and instead of being made of heavy, stiff material, they’re lightweight and flexible.

This makes the blades cheaper, but also allows them to bend away from the tower during heavy winds, without breaking.

“We are very much bio-inspired by palm trees, which can survive these hurricane conditions,” said Lucy Pao, a researcher at the University of Colorado Boulder.

The prototype: The researchers have now released four year’s worth of data from SUMR-D, a prototype built at the National Renewable Energy Laboratory’s Flatirons Campus in Colorado.

According to the team, the 53.38 KW demonstrator was able to sufficiently and consistently generate electricity during peak wind speeds, which can reach up to 100 miles per hour in the area — about what you’d expect during a Category 2 hurricane.

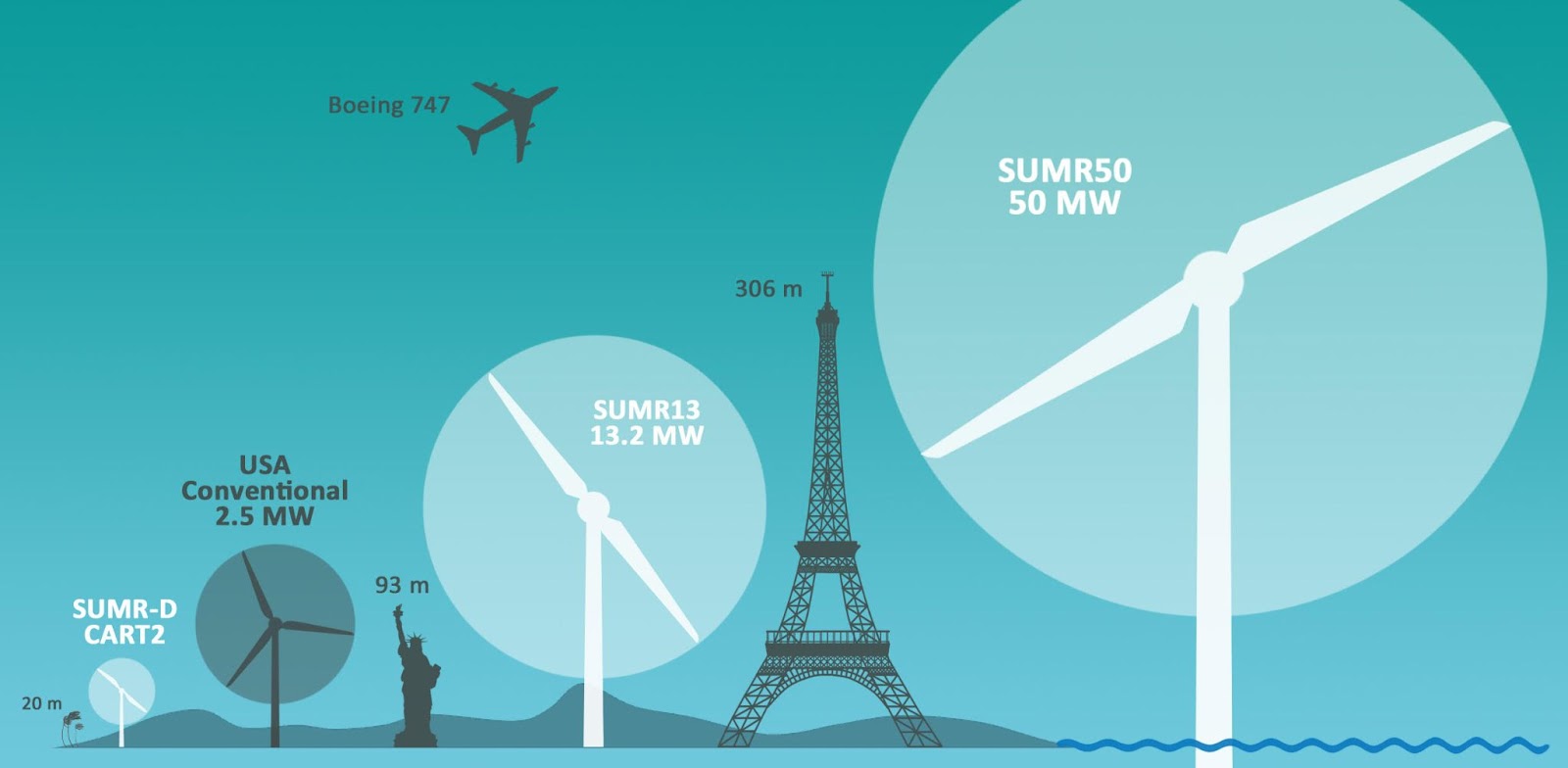

The team plans to conduct more research with the prototype, with the goal of demonstrating that their design could enable cost-effective 50 MW offshore wind turbines — absolutely dwarfing today’s offshore turbines, which typically max out at 8 MW.

“[T]he size of that would be like the Empire State Building, even larger,” SUMR researcher Eric Loth told Marketplace in 2018. “So you’re talking about being able to power a small city with one of these wind farms. And I think that’s where we’re going. That’s where the future is.”

We’d love to hear from you! If you have a comment about this article or if you have a tip for a future Freethink story, please email us at [email protected].