You can think of your bones as being like an apartment building — from the outside, all you see is this hard, inorganic structure, but it’s actually full of gaps in which living things reside.

The living residents, in the case of bones, are marrow cells, and the inorganic structure is mostly a mix of two minerals: calcium and phosphate.

That design has traditionally made creating synthetic bones for people in need of replacements tricky. Doctors would first have to fabricate the rigid part of the bone and then add in the living cells before implanting the whole thing into a person and hoping for a perfect fit.

In the future, though, they may be able to use a new 3D bioprinting technique to print a replacement bone containing living cells directly inside a patient’s body.

“This has the potential to radically change current practice, reducing patient suffering, and ultimately saving lives,” Kristopher Kilian, who co-developed the technique, said in a press release.

What Is 3D Bioprinting?

3D bioprinting is similar to 3D printing in that a printer layers “ink” to construct a three-dimensional object.

The difference is the kind of ink used — while most 3D printers work with plastics and other inorganic materials, 3D bioprinters use “bioinks” of living cells.

Using 3D bioprinting technologies, researchers have created corneas, mini organs, human ears, and more — they’ve even bioprinted human tissue in space.

Now, Kilian and others at the University of New South Wale (UNSW) Sydney have developed a new 3D bioprinting technique for bone.

It’s All in the Bioink

The key to the new technique — called “ceramic omnidirectional bioprinting in cell-suspensions” (COBICS) — is the custom bioink.

This ink contains calcium phosphate, and at room temperature, it has a paste-like consistency. When exposed to a liquid, though, it hardens into a porous structure, similar to natural bone.

The conversion is quick and only initiates when the ink is exposed to body fluids.

Iman Roohani

The idea is that surgeons could print the bioink right into a patient’s body where new bone is needed, and their cells will integrate with the material as it hardens.

This would eliminate the need to create a new bone outside the body, lace it with living cells, and then implant it.

“The ink is formulated in such a way that the conversion is quick, non-toxic in a biological environment, and it only initiates when ink is exposed to the body fluids, providing an ample working time for the end-user, for example, surgeons,” COBICS co-developer Iman Roohani said in a press release.

Looking Ahead

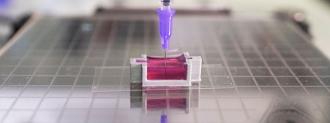

Using an off-the-shelf 3D printer equipped with a special nozzle, the researchers have demonstrated their bioprinting technique in a gel containing live cells.

Next, animal studies will test if the living cells in their 3D bioprinted bone continue to grow after the procedure.

If so, they envision a future in which surgeons could use the COBICS technique to treat patients with bone damage due to trauma, cancer, or other diseases.

“I imagine a day where a patient needing a bone graft can walk into a clinic where the anatomical structure of their bone is imaged, translated to a 3D printer, and directly printed into the cavity with their own cells,” Kilian said.

We’d love to hear from you! If you have a comment about this article or if you have a tip for a future Freethink story, please email us at [email protected].