A Bill Gates-backed startup has come out of stealth with a new carbon removal tech it says is cheap, scalable, and durable — and if all that’s true, it could be the key to preventing the worst climate change scenarios.

The gigaton challenge: Just cutting greenhouse emissions won’t be enough to reach our climate goals, according to most experts — we need to remove and sequester a lot of carbon that we’ve already released into the atmosphere, too.

“Carbon Casting can remove billions of tons of CO2 from the atmosphere at an affordable price starting now.”

Barclay Rogers

Engineers have built direct air capture (DAC) systems that can pull CO2 from the air with giant machines, but they are both energy intensive and expensive — capturing and storing just one ton of CO2 with them is currently estimated to cost between $600 and $1000.

That really adds up when you consider we need to be removing about 85 million tons of CO2 from the atmosphere every year by 2030, according to the IEA, and almost 1 billion tons by 2050. All of today’s DAC systems combined sequester just 10,000 tons annually, and the tech isn’t that easy to scale up.

Carbon Casting: Bill Gates-backed startup Graphyte has developed a technology, called Carbon Casting, that it says is scalable and capable of removing carbon at a cost of $100 per ton — the price at which experts say carbon removal tech becomes economically feasible.

“We need a solution that can scale immediately without using a lot of energy … Carbon Casting can remove billions of tons of CO2 from the atmosphere at an affordable price starting now, delivering a much-needed solution to combat climate change,” said CEO Barclay Rogers.

How it works: Carbon Casting takes advantage of the natural kind of carbon capture: photosynthesis, where plants pull carbon dioxide from the atmosphere.

Graphyte’s process starts with the collection of waste biomass, such as rice hulls, scrap lumber, and sawdust, from the agricultural and timber industries. Typically, this material is burned or allowed to decompose, which releases the carbon trapped in it back into the atmosphere.

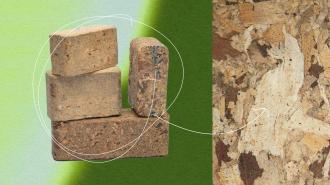

Because the microbes that drive decomposition can’t live without water, Graphyte dehydrates the material before compressing it into tight blocks. The blocks are then wrapped in an impermeable barrier and stored underground.

“It is a polymer barrier that has been designed to have the right durability properties [and] diffusion properties against moisture, oxygen, methane, etc.,” Chris Rivest, a partner at Gate’s Breakthrough Energy Ventures, told TIME.

“This is one of the approaches that was really purpose built to solve the long term problem of carbon capture.”

Chris Rivest

While most other carbon removal tech involves injecting captured CO2 in specific types of geological formations underground, Graphyte has much more flexibility in where it could build its underground chambers — the company envisions putting them under farms or solar installations.

Graphyte plans to include sensors and tracers that can monitor for signs of decomposition inside the chambers, but it is confident that the blocks created through Carbon Casting will be able to trap carbon for centuries.

“We’re able to perform what’s called accelerated aging testing,” Rogers told TIME. “This is effectively simulating the environmental stresses that the materials would see over 1,000 years.”

Looking ahead: Graphyte expects to wrap construction on its first pilot plant in Pine Bluff, Arkansas, in 2024. Initially, it will operate at a rate that could capture and store 5,000 tons of CO2 per year, but the company hopes to ramp up to 50,000 tons before the end of 2024.

As for how much carbon the startup could ultimately be storing, Graphyte says there’s enough waste biomass in the world to remove 3 billion tons of carbon every year. Storing any appreciable fraction of that could be a big help in combating climate change.

“This is one of the approaches that was really purpose built to solve the long term problem of carbon capture,” said Rivest.

We’d love to hear from you! If you have a comment about this article or if you have a tip for a future Freethink story, please email us at tips@freethink.com.